TWH – COVID-19 shutdowns have decreased revenue for recycling centers. More profitable commercial recycling has decreased while less profitable residential recycling has increased. This decline has occurred on top of the international recycling markets on the verge of collapse.

China had imported more material for recycling than any other country. In 2017, China announced that it would ban imports of material for recycling. Much of the material it had imported was contaminated and had become a pollution problem for China. This unequal exchange conflicts with the Pagan value of reciprocity.

Modern Pagan traditions rely on common practices and values. One value has many names for its many aspects: generosity, hospitality, reciprocity, and mutual obligation, among others. Most people think of hospitality as occurring between individuals. Yet, reciprocity can occur between social groups or countries.

The recycling industry

According to an article published by Vox.com, the recycling industry is a $200 billion industry. It transports plastic and other waste across the globe. Consumers separate material for recycling from other trash and place that material in marked recycling containers. Front-end recycling companies pick up that material. Then, they make it ready for distribution to back-end recycling centers, which process the material for re-use.

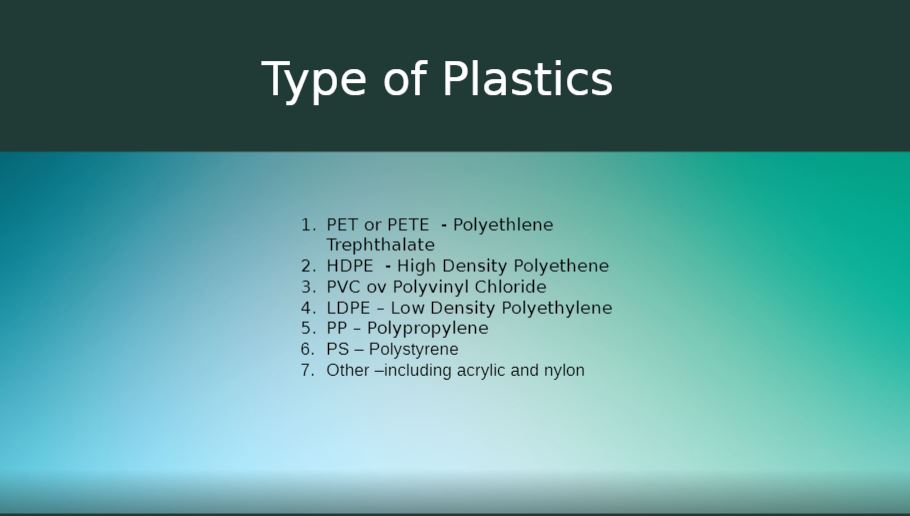

Front-end recycling centers sort the material into glass, metal, paper, and plastic streams. With minimal processing, workers can put glass, metal, and paper scrap into bales. They then ship it to back-end recycling companies. Plastic requires more processing. Workers have to sort plastic by type of plastic. They have to bale each type separately to ship to back-end recycling centers.

A report produced by Fortune Magazine in partnership with the Pulitzer Center on Crisis Reporting outlines the issues the recycling industry is facing, and the impact it is having:

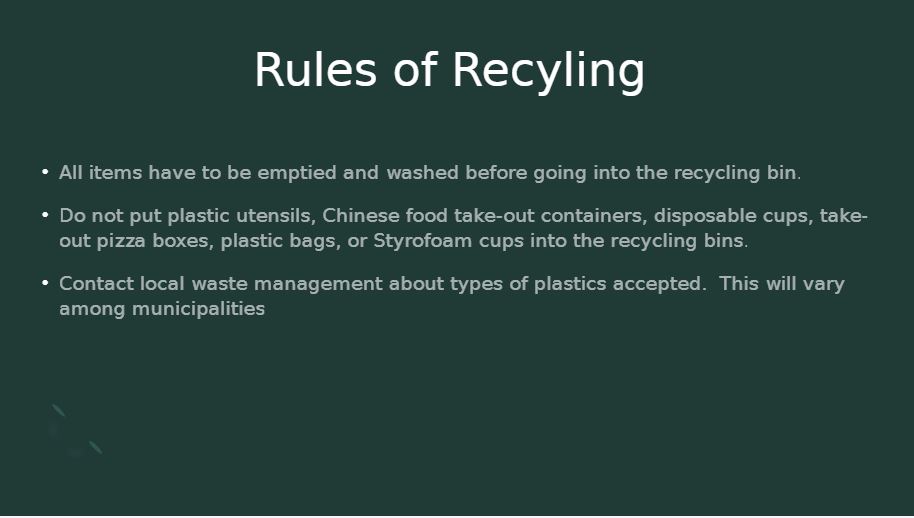

Single-stream recycling mixes glass, metal, paper, and plastic. While convenient for the consumer, the single-stream model increases the risk of contamination. Before putting it in the recycling bin, consumers are supposed to clean all material. Food containers may have grease, sauce, and bits of food stuck to them. Unclean food containers can contaminate everything else in the recycling bin. Contaminated material becomes just more pollution.

The process for plastic recycling

Front-end recycling uses an assembly line format. Workers put the material on a conveyor belt, removing items that might damage equipment or that are not recyclable. Machines sort materials into separate streams: glass, metal, paper, and plastic.

The glass, metal, and paper streams require minimal processing. Workers put material from those streams into bales of glass, metal, or paper. Then, those bales are shipped to back-end recycling centers.

Plastic requires a second sorting by plastic-type. The bottom of every plastic item has a numerical code. That code shows the type of plastic. Each type of plastic requires its own bale. Some back-end plastic recycling centers only deal with one type of plastic.

At a back-end plastic recycling center, machines shred the plastic into small pieces. Next, it is washed. A metal detector scans those small pieces for traces of metal. After washing, the small pieces of plastic are melted. After melting, one of two further processes will occur. In one process, the melted plastic is extruded through a wire screen to create spaghetti-like strands. In another process, it is made into pellets, cooled, dried, and stored. Workers can then send either the pellets or strands to a plastics manufacturing plant. There, it will become another plastic item.

Impact of COVID-19

The Los Angeles Times reported that out of 17 recycling centers, only five remain open in Los Angeles. COVID outbreaks among staff and financial difficulties have driven these closures. In Los Angeles, residential waste has increased between 15% and 20%. Commercial waste has decreased by 15%. Los Angeles residents tend to pay a flat amount. In contrast, commercial enterprises pay by volume. As a result of low oil prices, “virgin” polyethylene terephthalate (PET) plastic made from oil costs less than recycled material.

The collapse of the markets

Before 2017, the European Union was exporting 95% of its plastic waste to China. The U.S. was exporting 70% of its plastic waste. U.S. exports of plastic scrap to China amounted to had 250,000 tons. By the spring of 2019, the U.S. was exporting almost no plastic scrap to China.

According to the Yale School of the Environment, China had recycled about half of the world’s recycling, which contained a large amount of contaminated material. China had, in effect, been importing pollutants from the West, and was now stuck with what could not be recycled.

Municipalities pay front-end recycling companies to take scrap from their recycling bins. The collapse of the international recycling market has left front-end centers without customers. In response, front-end recycling centers have begun to raise the prices that they charge municipalities.

Some municipalities can no longer afford to recycle. With nowhere to export the waste, incineration of waste products has increased, and some material from those recycle bins now ends up in landfills.

According to the New York Times, the largest front-end recycling companies, Waste Management and Republic Services also own landfills and collect trash. Landfills and incineration produce large revenue streams. Recycling does not. This market collapse has driven efforts to limit the use of plastic. These efforts include banning plastic bags and straws.

The SUEZ recycling plant opens

In contrast, one Asian country is expanding its domestic recycling operations. Thailand has built a new back-end recycling center. It appears to be for domestic plastic pollution rather than imported recycling. In December of 2020, the Suez company opened the SUEZ Circular Polymer Plant in Thailand. Currently, Thailand produces 2,000,000 tons of plastic waste annually. It only recycles 500,000 tons. That plant will only recycle low-density polyethylene (LDPE) and linear low-density polyethylene plastic (LLDPE).

Poor health of recycling before 2017

Even before the pandemic, the international recycling markets showed no signs of health or efficiency before 2017. Recycling never absorbed much of global plastic production. The world only recycled 9% of plastic. It incinerated 12%.

Before 2017, about a quarter of the world’s mismanaged waste occurred in China. That mismanaged waste did not all originate in China and the Chinese ban on importation now returns the problem to its source.

The Wild Hunt is not responsible for links to external content.

To join a conversation on this post:

Visit our The Wild Hunt subreddit! Point your favorite browser to https://www.reddit.com/r/The_Wild_Hunt_News/, then click “JOIN”. Make sure to click the bell, too, to be notified of new articles posted to our subreddit.